Zero-Trust Supply Chains Explained

As digital networks become increasingly prevalent in the day-to-day business world, so too does the threat of cyber attacks.

These efforts to steal or damage data are worrying for many.

The electronics sector is particularly vulnerable, as its complex supply chain of cloud platforms and software tools often lacks full visibility. One weak link can be targeted to cause expensive damage and reputational harm to large corporations.

Cue the rise of zero-trust supply chains.

What Is a Zero-Trust Supply Chain?

A zero-trust supply chain involves taking a pessimistic approach to who you can and cannot trust in your supply chain. Put simply, a zero-trust supply chain operates on the assumption that no internal or external entity can be trusted. This means that each incoming communication, request, and component needs to be continuously validated and authenticated.

Cybersecurity Ventures predicts that the global annual cost of software supply chain attacks on companies will amount to $138 billion by 2031. The risks are clear when considered in financial terms, which is why a zero-trust supply chain is growing in popularity.

In the context of the electronics supply chain, a zero-trust supply chain can be implemented in numerous ways, including:

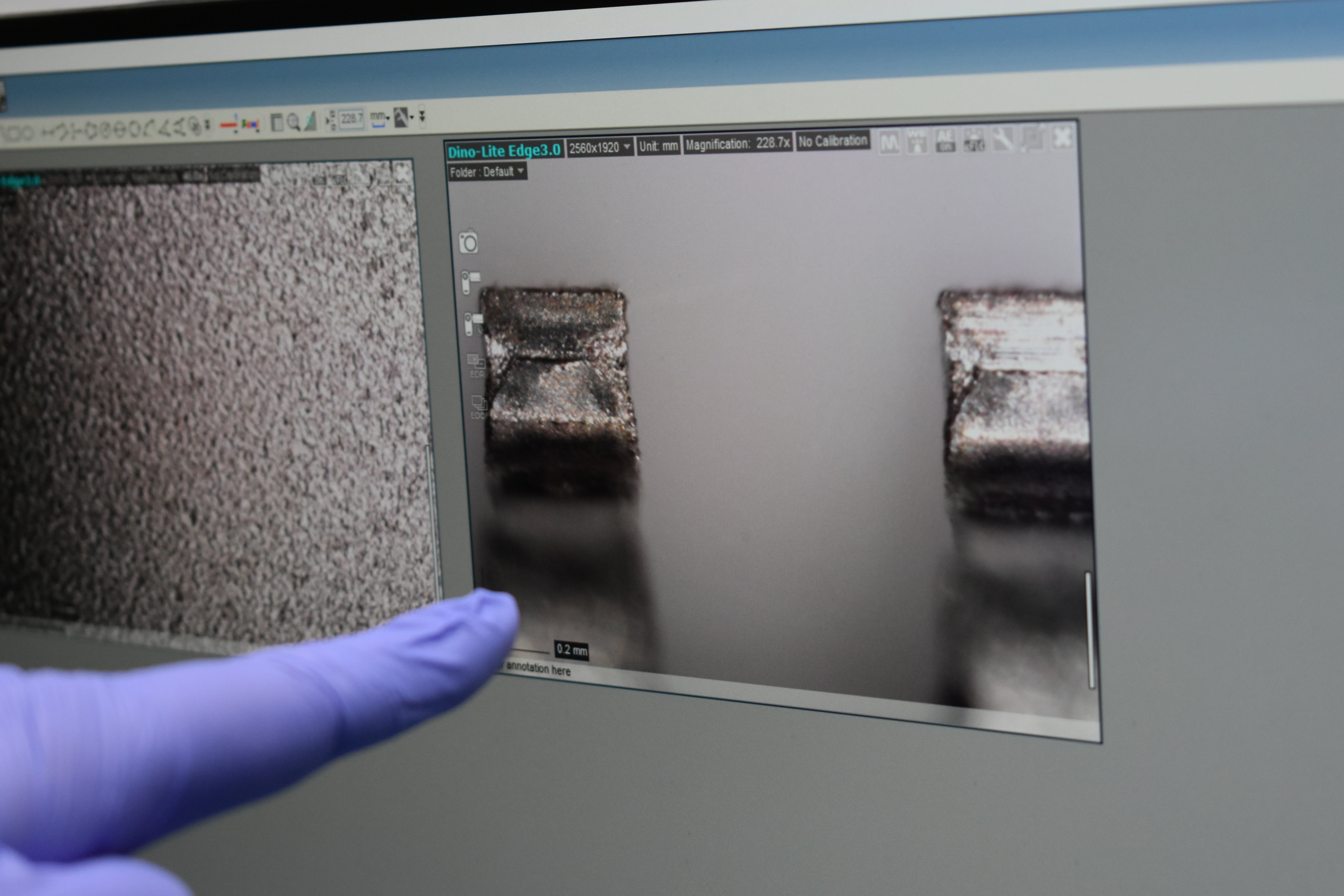

- Inspecting components for authenticity by insisting on full traceability and rigorous quality assurance testing.

- Scrutinising systems and software before implementation and continuously verifying them through dynamic permissions and segmented access.

- Treating suppliers as untrusted by default, verifying them through background checks and strict access controls.

- Strict and thorough cyber and operational security is implemented and adhered to as non-negotiable. Best practices, including real-time threat detection, are introduced.

Benefits of a Zero-Trust Supply Chain

Some estimate that the value of the zero-trust market will increase to $126 billion by 2031. With growing concerns regarding supply chain security, you can understand why. Some of the specific benefits of a zero-trust supply chain to electronic manufacturers include:

- Each component is verified before entering the production line, which ensures reliability. This is particularly crucial in industries like aerospace, defence, and medical device manufacturing industries.

- There are long-term savings resulting from fewer production delays and potential product recalls. These savings generally far outweigh the initial costs of moving to a zero-trust supply chain.

- Quick identification of cyber security breaches so that threats can promptly be eliminated.

- A zero-trust approach fosters a more resilient supply chain, ready to withstand geopolitical, environmental, or logistical disruptions.

The Role of Component Sense in a Zero-Trust Supply Chain

The secondary market for electronic components can sometimes get a negative reputation due to the presence of counterfeit components. However, by only working with trusted suppliers like Component Sense, you can enjoy all of the financial and sustainability benefits of secondary market procurement without the risks.

Component Sense fits perfectly within a zero-trust supply chain for many reasons. We only redistribute and sell components that are fully traceable back to the original manufacturer. Each part is untouched, brand-new, and backed by a counterfeit-free guarantee. Our final safeguard is a quality inspection process with over 100 touch points, developed alongside top Scottish universities.

By choosing to work with us, you can save money when filling out your BOM (bill of materials), have access to hard-to-find components, and positively contribute to reducing electronic waste.

Futureproof your supply chain

As supply chains continue to become more complex and cloud-based, the threat of cyber attacks also increases. A zero-trust supply chain may sound overly cautious by name; however, in reality, it is a pragmatic mindset where due diligence is carried out with each partner and supplier, and every component and material is checked for authenticity.

Setting up your supply chain with the proper protective measures can make your operations more resilient in the long term and lead to eventual cost savings. A proactive mindset is key.