Why a Sustainable Supply Chain Benefits Business

The global climate crisis can feel overwhelming.

We are all facing extreme weather events, habitat destruction, rising energy costs, and increasingly ominous predictions for the future of our planet.

Despite these climate issues, many corporations and governments remain tentative in their approach to climate-positive solutions. Whilst businesses are willing to adopt cycle-to-work schemes and recycling initiatives, these measures are minimal compared with the major culprits of climate change: mass production and global industrialisation.

From the point of view of many companies – particularly manufacturers – climate positivity and profit are mutually exclusive. Author and entrepreneur John Elkington, however, disagrees. Elkington’s sustainable accounting framework named the Triple Bottom Line (TBL), “examines a company’s social, environmental, and economic impact.” Elkington underlines that a sustainable approach has the potential to reap benefits not only for the planet but also for the people and profit margins of any business (Figure 1).

Figure 1. “Sustainability Framework.” Olena Avramenko.

The ‘3 Ps’ of the TBL are:

- People: the impact an organisation has on its stakeholders

- Planet: the impact an organisation has on its natural environment

- Profit: the impact an organisation has on the local, national, and international economy

Companies that embrace this transformational framework can ultimately make their business more sustainable and resilient for the future. By examining their impact on people, the planet, and profit, positive changes in each of these categories will naturally ‘reinforce one another’ and consolidate any corporation's capacity for success.

Those of us within electronics must admit that our industry is not the most environmentally friendly. We need to manufacture products, and our bills of materials contain increasingly rare minerals that require huge amounts of energy to procure. Our reliance on natural and manufactured materials, as well as on international shipping and cheap labour, might make our implementation of the TBL an uncomfortable one. One area of the electronics industry which can easily be made more sustainable, however, is the global supply chain.

According to CDP Worldwide, a charity that promotes corporate environmental disclosure, the impact of end-to-end supply chains on emissions is more than five times that of companies’ direct operations (quoting from the Boston Consulting Group). We are all aware that the international supply chain has been in a state of uncertainty in recent years, due to high demand and low supply. It is possible that, due to these supply chain issues, companies have resorted to environmentally damaging measures to secure materials. This approach may appear to ease the pressure of supply and demand, but it is fundamentally counterproductive.

A streamlined supply chain would not only allow businesses to navigate these issues more effectively but could reduce the overall environmental impact of our industry. Chris Jones, writing for Global Trade Magazine, underlined that, “successful companies recognise that improved supply chain performance and betterment of the environment go hand-in-hand; CO2 reduction is an opportunity for savings and improvements across the board: efficiency, cost, time, resources, and, of course, environmental.”

Not only will an improved supply chain benefit business, but it has been shown to result in increased customer satisfaction. Research from the Boston Consulting Group (BCG) found that “70% [of consumers] say they are willing to pay a 5% price premium for products produced by more sustainable means.” Consumers are actively changing their buying habits to be more sustainable, so companies that keep up with these environmentally focused demands will ultimately outlive their competition.

A sustainable approach to business has further benefits for the people within a company. Employees – especially those between the ages of 20 and 35 – are increasingly influenced by the environmental efforts of their workplace, with 35% of UK employees “willing to quit their job if their employer takes inadequate action to reduce its carbon footprint.” Environmentally conscious employers have been shown to attract top talent, and most importantly, retain it.

A sustainable supply chain, therefore, can have many advantages: making both environmental and business sense. So, how can companies within the electronics industry optimise their supply chain and improve their company’s environmental credentials?

BCG summarise a portfolio approach to improve environmental performance across the supply chain.

Their advice is to:

- Invest in innovative product design and packaging

- Work with sustainable suppliers

- Optimise the supply chain network

- Adopt circular economy models

- Take stock of operational resources and work to increase efficiency

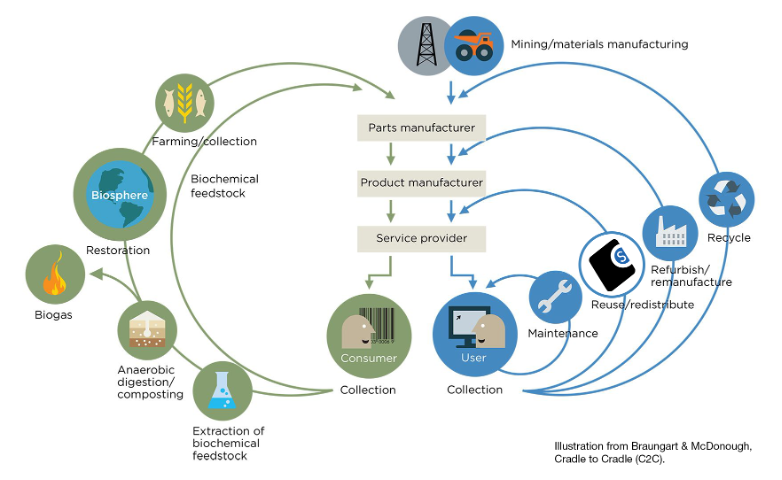

All of the above suggestions have the potential to dramatically reduce the carbon emissions of the electronics industry, an industry dependent on finite resources. Alongside eco-friendly packaging, an optimised, circular supply chain is a critical step in making the electronics industry more sustainable (Figure 2).

Figure 2. “Circular Economy Model.” Braungart and McDonough.

According to the Ellen MacArthur Foundation, a charity committed to creating a circular economy, circularity is based on three principles:

- Eliminating waste and pollution.

- Circulating products and materials (at their highest value).

- Regenerating nature.

In 2022, the global electronics industry produced a staggering 59.4 million metric tons of e-waste. Reducing electronic waste is an area of the industry that is, fortunately, being addressed by manufacturers, indicating that there are positive steps being made towards circularity. Whilst OEMs and EMSs currently cover the costs of recycling waste electronics, an often-overlooked problem is the production of excess and obsolete components (E&O). In a typical factory, E&O parts account for approximately 10% of annual revenue at any given time and can represent up to $100M worth of stock in large companies. Most often, unfortunately, these components end up being sent to landfill, or at best, are recycled for 0.1% of their original value.

Much of this E&O stock could easily be redistributed into the hands of other manufacturers and can typically be resold returning 100% of its value. To facilitate circularity, therefore, it is important to prioritise models of reuse and redistribution, which minimise the number of excess electronic parts being sent to landfills. This in turn reduces the release of harmful chemicals into the environment, minimises opportunities for counterfeiters, and lessens the environmental impact of manufacturers (as they avoid overproduction). Many organisations within the electronics industry work exclusively with excess and obsolete components, for example, Component Sense.

When choosing your E&O redistribution partner, it is also important to remember all elements of the triple bottom line. How does the company impact its people? The planet? The local and wider economy? Bearing these questions in mind will help electronic manufacturers find the most sustainable and resilient businesses for critical partnerships.

Proxima — a supply chain consultancy group — has succinctly stated: “Supply chains are complex, they are part of the problem, but they are also the biggest part of the solution. [Companies] can lead the way internally and externally to force positive change, a journey that will resonate with staff, customers, and investors alike.” Making your supply chain more circular and environmentally friendly, then, can benefit all areas of your business, particularly its impact on the planet, people, and profit!

Morag Dine is Marketing Manager at Component Sense. We are an electronics redistribution company specialising in excess and obsolete components, intending to lead manufacturers toward zero waste. If you are interested in learning more about how Component Sense can help make your electronic manufacturing business more sustainable, you can contact her here: marketing@componentsense.com