InPlant™ by Component Sense: Making your Business more Efficient, Profitable, and Sustainable

At Component Sense, we are committed to innovation. This drive to continuously improve our business processes led us to create our unique InPlant™ system. We designed InPlant™ to help Original Equipment Manufacturers (OEM) and Electronics Manufacturing Services (EMS) customers manage their excess and obsolete stock (E&O). We know that excess inventory is a constantly depreciating asset: unfortunately, millions of tonnes of electronic components end up in global landfills each year. Component Sense decided to create InPlant™. InPlant™ is a system that relieves our largest customers of the environmentally damaging and often overlooked burden of excess stock management.

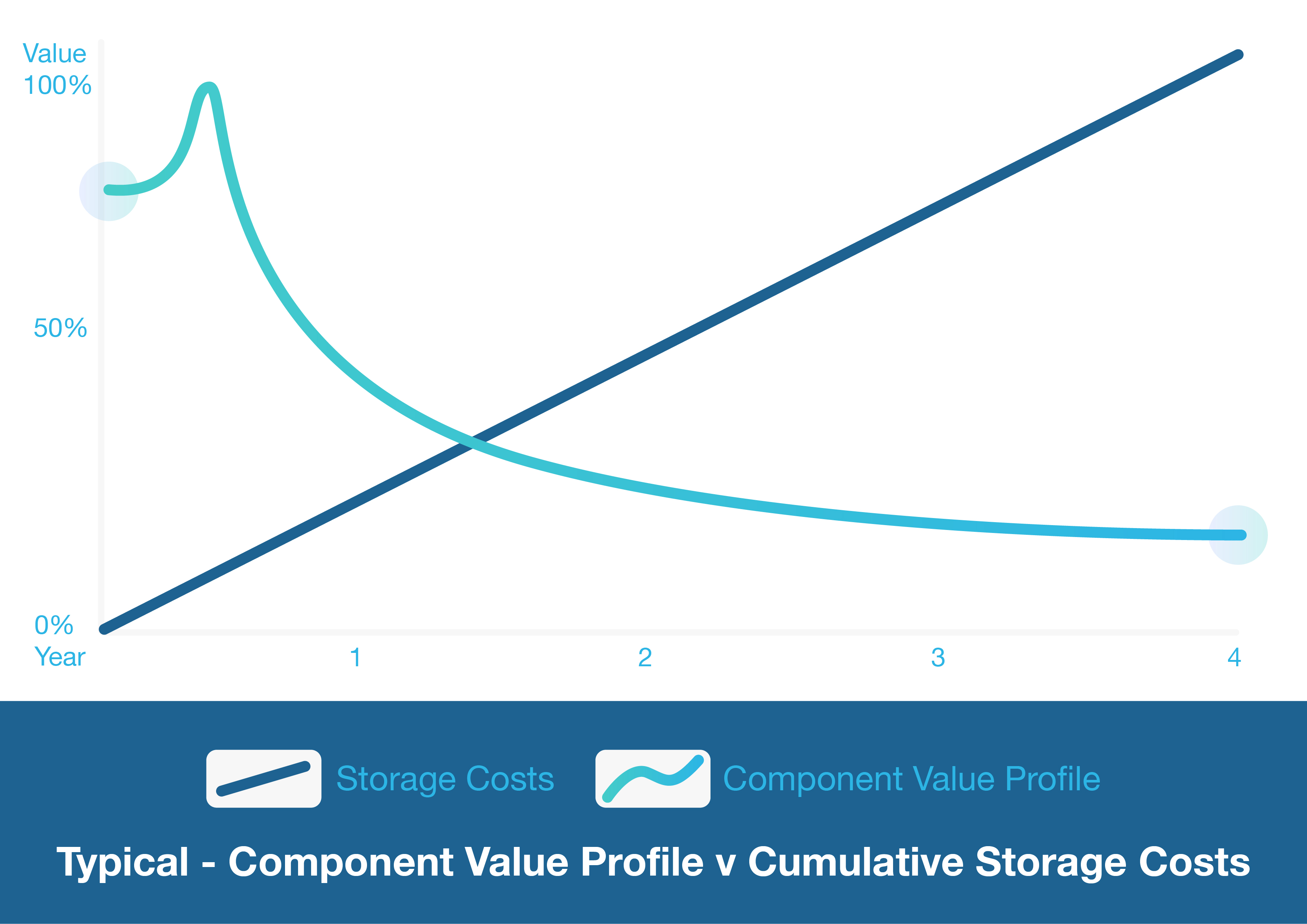

We know that excess inventory is a constantly depreciating asset.

We know that excess inventory is a constantly depreciating asset. In short, Component Sense’s InPlant™ system is an inventory management tool. By combining automated software with our expert industry knowledge, we can help identify true excess in large businesses at the earliest possible stage. By dealing with excess stock early, we can resell newer components and are therefore more likely to achieve a return on cost or even make a profit. That helps everyone in the industry chain, as we simultaneously minimise E&O and provide new stock at a reasonable price, whilst ensuring a profitable return for manufacturers. By installing InPlant™ within OEMs and EMSs, Component Sense can update inventory systems on a live, automatic basis. We can therefore advertise components which are ‘in stock’ rather than ‘available’ (as is most often seen on the market), a much more attractive option to potential buyers.

Grant Rutherford, Component Sense’s Chief Technology Officer, sums up the benefits of InPlant™ as a way for our company to “move your stock with minimal fuss.” By installing InPlant™ within customers’ stores (rather than relying on availability lists), our customers can be relieved of the pressures of excess stock holding and assured of their inventory control. Grant says:

Component Sense CTO, Grant Rutherford

Component Sense CTO, Grant Rutherford“The best thing about InPlant™ is that it sums up what Component Sense is all about. My team and I came up with this bespoke automated system to allow us to move excess stock quickly, and at the same time guarantee full traceability and security. Integrity and clarity are key values at Component Sense, and InPlant™ means we can provide this to customers. We offer InPlant™ to large businesses, and we do the hard work of E&O management for you while at the same time increasing working capital. At the end of the day, we made InPlant™ to help our customers and make their businesses more profitable.”

Grant’s IT background means that InPlant™’s automated software can be integrated into any Manufacturing Resource Planning (MRP) system. We then take the complete job off your hands by training a dedicated team member to manage InPlant™ within our customers’ stores. As Grant says, only the InPlant™ system can “manage your entire problem and deliver additional profit to your business.”

Finally, InPlant™ is the most efficient way for Component Sense to meet our sustainability and e-waste goals. We are a company dedicated to environmental stewardship, and we are always looking for ways to minimise the damage to the environment caused by the electronics industry. By reducing E&O stock, we limit liability, waste, and the number of counterfeit components hitting the market. We care deeply about these outcomes. So, we are proud to say that InPlant™ benefits everyone in the electronic industrial cycle, from manufacturers to buyers, from consumers to the planet.

Why not watch this video to learn more about InPlant™?

If you are interested in becoming an InPlant™ customer, you can contact a member of our expert team here.

We would be glad to answer any questions and look forward to hearing from you!